The Challenge

An aerospace manufacturer of jet engine cones needed to improve the process for machining titanium cone that ranged in size from 60" in diameter and 84" long. Their current process required 4 weeks of machining time to produce each assembly.

The Solution

Drawing on Creative Automations extensive experience for dispensing unique materials, a process using a fluid mask and acid etching solution to achieve a paradigm shift in the manufacturing method used to produce the cones. Through a series of experiments it was determined that etching away the titanium was a considerably better manufacturing method than machining, if only a mask material could be dispensed accurately enough to emulate the machining process.

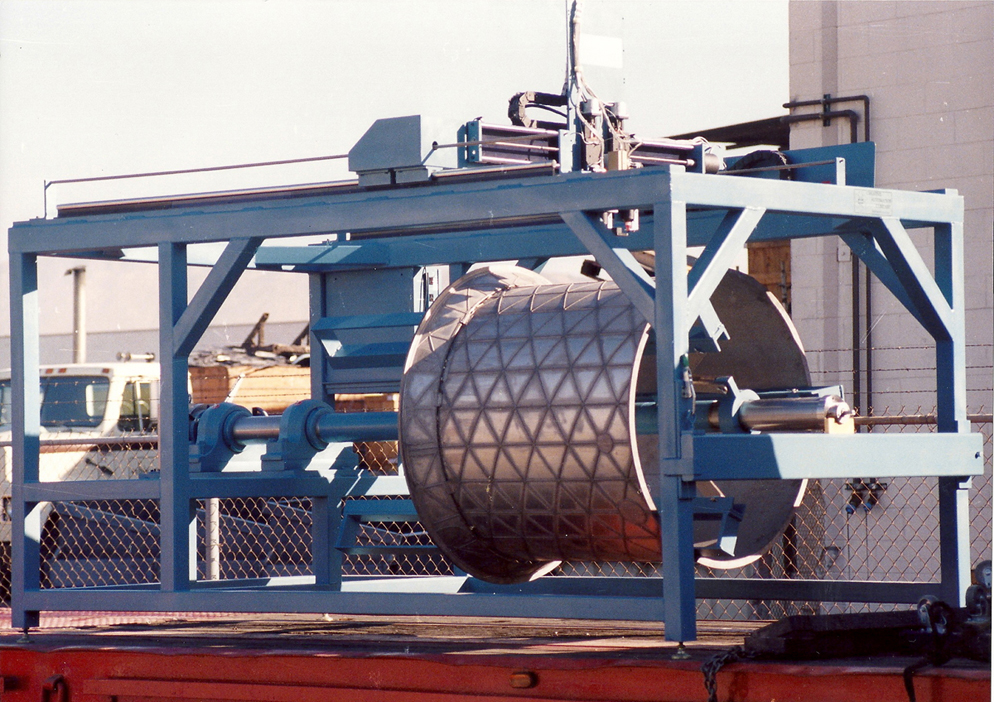

Creative Automation designed and fabricated a 4 axis automated fluid mask dispensing system. The process begins by dispensing a basic pattern onto a titanium cone. Next the cone is etched to a depth of approximately 0.060" to remove material. Additional passes of precision dispensing and etching produced the required thickness reduction geometry without thinning the support ribs. Processing time was improved by 500%